In Florence since 1956 as an artisan producer of accessories for leather goods and costume jewelery.

In 1978 the company moved to Scandicci, with the construction of the first automatic galvanic plant.

In 1988 the first numerical control machine was implemented in the company's production.

Year after year the growth does not stop: thanks to the progressive expansion of the company departments, the continuous innovation of the machinery and the desire to respond professionally to the evolution of the sector, Andrei Srl is today among the national leaders in its market sector.

ONE EYE TO THE FUTURE

Constant innovation is the essence of our work

Our ideas could not remain hidden, which is why we decided to also implement prototyping in production, which we carry out directly in our laboratories.

OUR STRENGTHS

The main traits that made us great

Quality

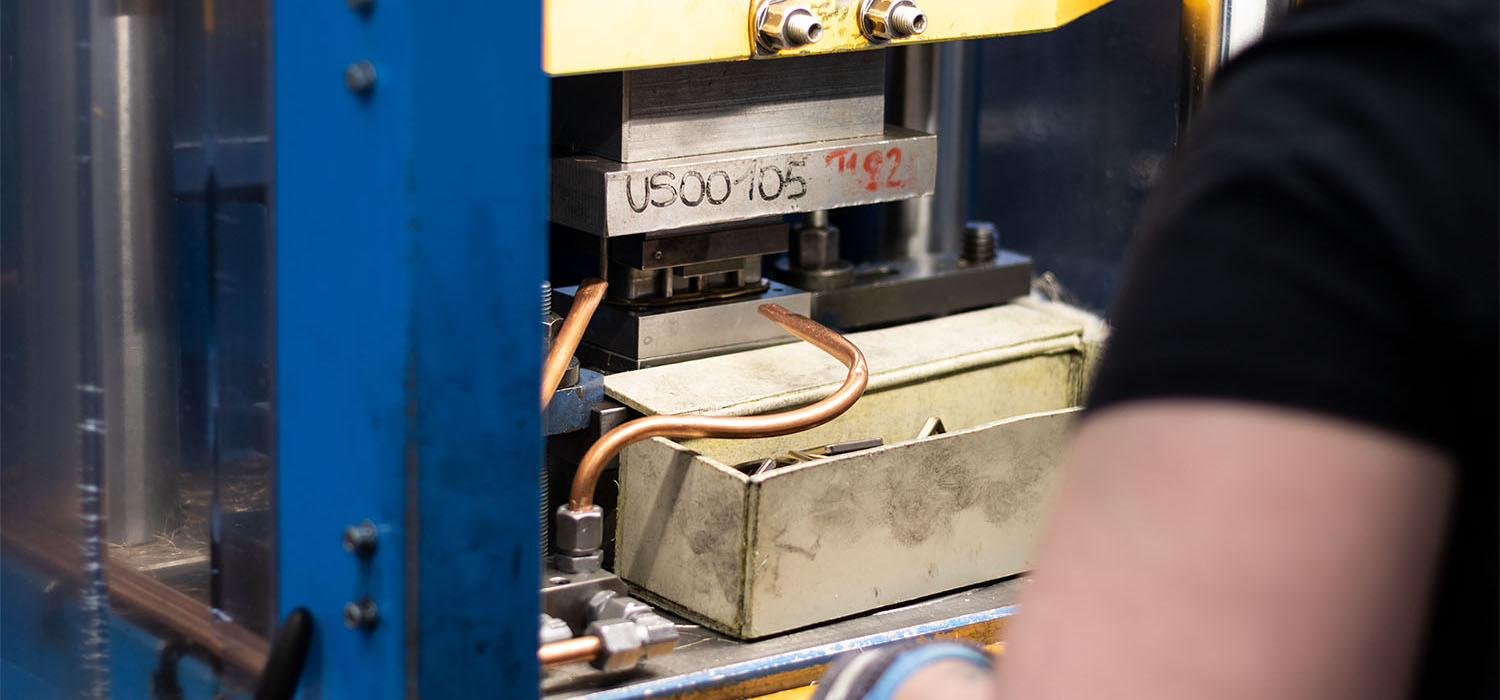

The monitoring of the operating parameters of the entire production process, from the raw material to the finished product, allows to guarantee high efficiency and compliance of the articles with the required technical specifications.

The galvanic treatments satisfy the aesthetics and performance of resistance and durability required by customers. The need to have a wide range of finishes and to satisfy special requests with dedicated colors is solved by the company by combining the automatic production line with the manual one performed by skilled collaborators.

The galvanic treatments satisfy the aesthetics and performance of resistance and durability required by customers. The need to have a wide range of finishes and to satisfy special requests with dedicated colors is solved by the company by combining the automatic production line with the manual one performed by skilled collaborators.

Experience

Experience is always synonymous with merit and reliability , this is what distinguishes us. Since 1956, we have put into our work every day the commitment necessary for the realization of our processes.

By virtue of this daily application, for over 60 years we have gained that experience that we proudly show, an essential value for working in symbiosis with world-class companies.

Expanding and innovating will always remain our main objective, an ambition made possible by the solid base of know-how on which we are founded.

By virtue of this daily application, for over 60 years we have gained that experience that we proudly show, an essential value for working in symbiosis with world-class companies.

Expanding and innovating will always remain our main objective, an ambition made possible by the solid base of know-how on which we are founded.

Versatility

Our company has mainly worked brass as a material and over the years we have combined brass with alternative materials, useful for embellishing the metal accessories offered on the market, such as wood, plexiglass and plastic materials.

Thanks to the goldsmith workers present, we also produce 925 silver jewelry.

In relation to the needs of the market, in recent years the processing of zamak has also been introduced, managing to create accessories of aesthetic quality comparable to brass.

Thanks to the goldsmith workers present, we also produce 925 silver jewelry.

In relation to the needs of the market, in recent years the processing of zamak has also been introduced, managing to create accessories of aesthetic quality comparable to brass.

Dynamism

Our company has always transformed the customer 's style ideas into "industrialized" items, made with the "artisan" care that distinguished us in the past and will distinguish us in the future.

We have the necessary elasticity to be able to make any type of product, both in terms of size and quantity.

We know and respect the very short prototyping and production times required by the customer.

We have the necessary elasticity to be able to make any type of product, both in terms of size and quantity.

We know and respect the very short prototyping and production times required by the customer.

Vanguard

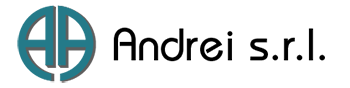

Being successful today requires increasingly bold investment decisions. In other words, it's about knowing how to make the right choices, anticipating and not chasing.

Proposing cutting-edge solutions is in our DNA, we offer innovative production ideas based on the latest technologies, we follow a flexible and modular approach and in compliance with the highest quality, safety and sustainability standards.

Proposing cutting-edge solutions is in our DNA, we offer innovative production ideas based on the latest technologies, we follow a flexible and modular approach and in compliance with the highest quality, safety and sustainability standards.

Historicity

Begun in 1956 as an artisan workshop in Florence, the history of Andrei Srl has developed to this day amidst the successes achieved over the years. Proud to have been artisans, even more proud to have kept those traditions now that we have become an established industry . We are convinced that in the next few years our growth will not stop, thanks to the progressive expansion of our departments , the continuous innovation of the machinery and the desire to respond professionally to the evolution of the sector, with an eye to the future and one to the past. .